Medical Industry : UDI Laser marking, Medical Grade Inks & Pad printing machines

The medical, Pharmaceutical, wellness and healthcare industry is a huge collection and coordination of enterprises that offer all goods and services to patients and customers for their health benefits, cure and care.

Healthcare system & medical industry deals with prevention, diagnosis and treatment for which many medical devices such as medical instruments and apparatuses are commonly used which needs to be printed or laser marked for gradation, scaling, white patch printing, calibration, markings, identification, branding, differentiation according to its use for sampling and traceability.

Materials that the medical devices are usually made of are FEP,PTFE,PFA,E-PTFE,Kapton, Polyamide, PEEK,PE, LDPE, HDPE,PP, Santoprene, ABS, PVC, glass and certain metals to name a few.

Spinks World is a One stop solution provider to the medical industry for printing and Laser marking.

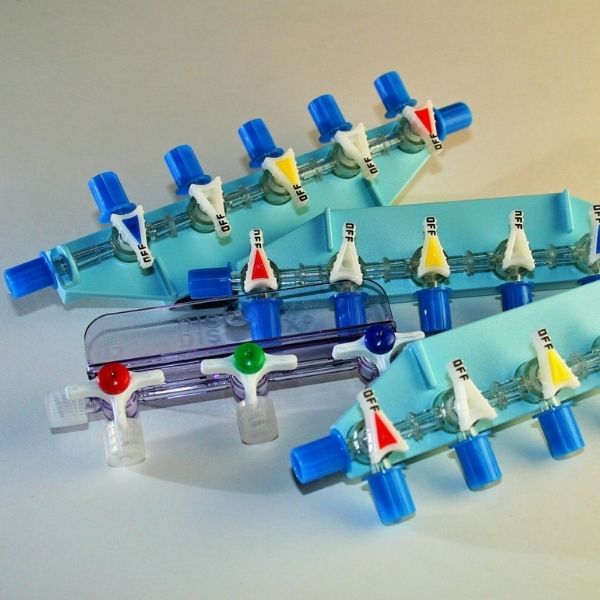

The medical products for which we can provide printing solutions are catheters, thermometer, syringe, face masks, glucose meter, first aid kit, scalpel, curette, pharmaceutical glass containers and medicine strips, lab wares like beaker, pipette, conical flask, pert plates, test tubes, measuring cylinder, stents, implants, centrifuge tubes, vials, Eppendorf pipette, shafts, clips, handles, adapters, medical housings, syringe kits ,connectors and many others.

Syringe Barrels,centrifuge tubes, Ampoules and covid testing kit are just a few examples of medical devices well suited for pad printing.

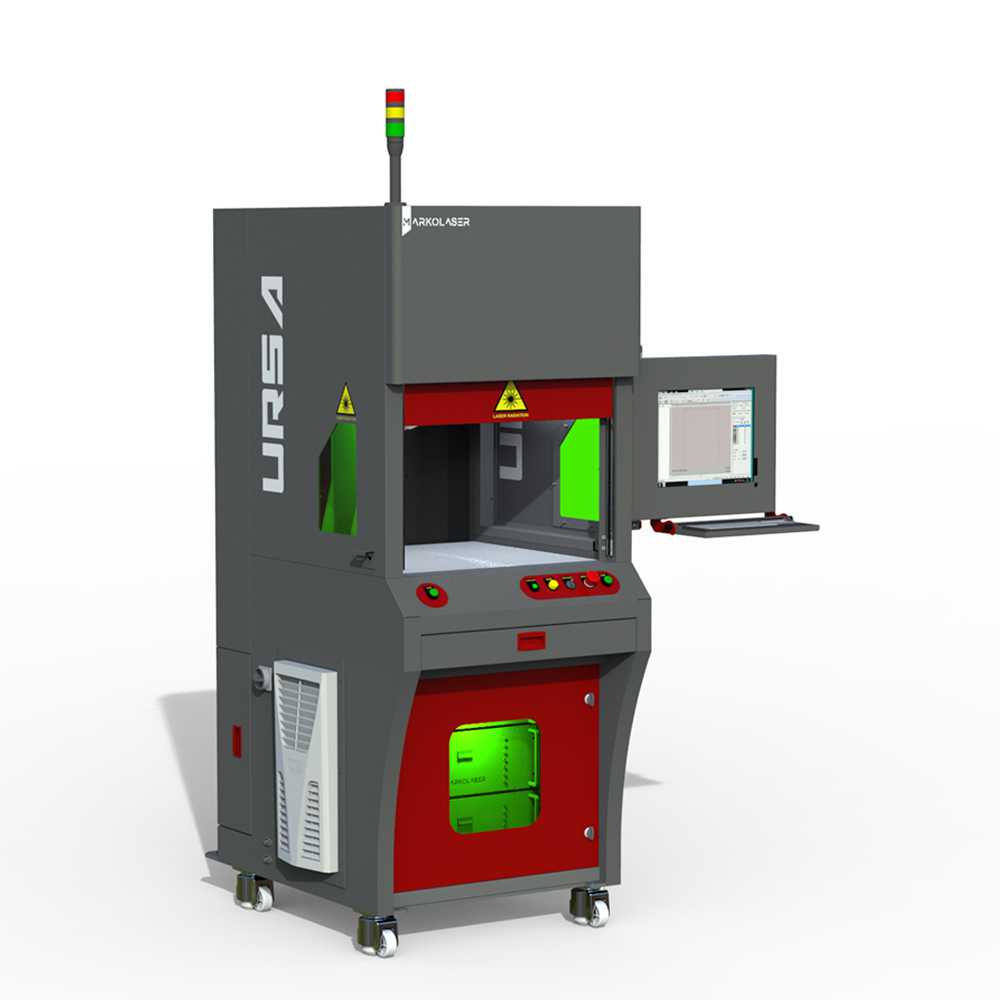

Laser Marking Solutions in medical industry for medical devices identification, patient health, medical implants, counterfeiting issues, drug safety, compliance with regulatory standards and privacy

Our engineering unit for lasers,provide you a marking compliant with UDI & MDR standards. It is corrosion and heat resistant, that doesn’t go away with time or on contact with acid. Lasers are engineered to do delicate and high precision marking regardless of complexity of patterns. It is a permanent marking that is tamper-proof and further doesn’t contaminatethe medical device’s hygiene. Markolaser offers you customized solutions to your specific problems, needs and requirements. Read More

Good quality with high contrast, & great machine-readability

Good Erosion Resistance

Resistive towards repetitive sterilization

Passivation Resistance

Perfect marking obtained and size adjustable

Laser Marked Samples

Sections In Medical Industry

Surgical instruments & equipments

Serializations or traceability of Surgical Instruments like Scissors, Forceps, Clamps, Needle Holders, Knives, Blades, Retractors and Fiber Optic Headlights is essentially demanding for Manufacturer.These instruments are made up of metals and plastic. Markolaser helps all the surgical instrument manufacturer by providing them Med Laser marker which is designed and configured according to UDI, MDR and FDA Standards and regulations.

Annealing on Dental Tool

Branding and UDI data matrix on Medical Peek and Orthopedic or trauma surgery implants

Trauma fixation PEEK is generally fabricated into bone plates, nails, anchors and screws. Orthopedic PEEK is one of the best replacement for metal while undergoing orthopaedic procedures, and particularly knee and hip arthroplasty. Dental PEEK, Cardiovascular peek, prosthetic peek, Hip-ball, Hip-stem, Bone screw all these peek require traceability.

Bone prostheses is the potential replacement of bones completely or partially. These bone prostheses are made up of substrates like non-reactive and non-corrosive metal, ceramic or highly cross-linked polymers. Whether they are metals like zircon or titanium, plastics or any polymer like polypropylene and acrylic they must follow all the medical compliance for traceability

Laser Marking Hygenic Peek

Marking on Fixation Peek

Marking on hipball implants

Medical Industry

The medical, Pharmaceutical, wellness and healthcare industry is a huge collection and coordination of enterprises that offer all goods and services to patients and customers for their health benefits, cure and care.

Healthcare system & medical industry deals with prevention, diagnosis and treatment for which many medical devices such as medical instruments and apparatuses are commonly used which needs to be printed or laser marked for gradation, scaling, white patch printing, calibration, markings, identification, branding, differentiation according to its use for sampling and traceability.

Materials that the medical devices are usually made of are FEP,PTFE,PFA,E-PTFE,Kapton, Polyamide, PEEK,PE, LDPE, HDPE,PP, Santoprene, ABS, PVC, glass and certain metals to name a few.

Spinks World is a One stop solution provider to the medical industry for printing and Laser marking.

The medical products for which we can provide printing solutions are catheters, thermometer, syringe, face masks, glucose meter, first aid kit, scalpel, curette, pharmaceutical glass containers and medicine strips, lab wares like beaker, pipette, conical flask, pert plates, test tubes, measuring cylinder, stents, implants, centrifuge tubes, vials, Eppendorf pipette, shafts, clips, handles, adapters, medical housings, syringe kits ,connectors and many others.

Syringe Barrels,centrifuge tubes, Ampoules and covid testing kit are just a few examples of medical devices well suited for pad printing.

What does Spinks World offer for printing and marking solutions to Medical Industry

Machines for printing and marking for the Medical Industry

EPIC Pad Printing Machine

Compact, simple, and environmental friendly high pressure pad printing machines

Markolaser medical laser makers

Our engineering unit for lasers,provide you a marking compliant with UDI & MDR ...

M-track identification & traceability platform

All the medical devices, surgical tools and instruments, medical implants ...

Printing inks solutions for Medical Industry

Pad printing inks

Disposable syringes, Ampoule, catheters , pipettes, counter rings

Screen printing inks

Glass ampoule, lab-ware, glass syringes, insulin, Glass products, high temperature products

Screen printing inks

inhaler, testing kits, medical jars, medical equipment

Screen printing inks

Lab coats, lab gloves, shirts, lab equipment, lab apparels

Screen printing inks

Plastic syringes, medical knifes, medical vials

One/Two-component, Screen Printing, Pad Printing and Spray Coating Inks

Disposable Syringes, Catheters, Test tubes, Centrifuge tubes etc.

Consumables for Medical Industry

Silicone Pads

Special silicone pads are used in the pad printing to transfer the precise, sharp & high resolution image from the cliche to the surface to be printed. ...All silicone pads are readily available on demand as they are 'Made in India' with International standards.

Cliché plates

Cliché Plate material, depth, size, toughness, lapping & etching and grounding are some key factors that make it perfectly suitable for pad printing ...based on the application for excellent printing results.

Surgical instruments & equipments

Serializations or traceability of Surgical Instruments like Scissors, Forceps, Clamps, Needle Holders, Knives, Blades, Retractors and Fiber Optic Headlights is essentially demanding for Manufacturer.These instruments are made up of metals and plastic. Markolaser helps all the surgical instrument manufacturer by providing them Med Laser marker which is designed and configured according to UDI, MDR and FDA Standards and regulations.

Annealing on Dental Tool

Branding and UDI data matrix on Medical Peek and Orthopedic or trauma surgery implants

Trauma fixation PEEK is generally fabricated into bone plates, nails, anchors and screws. Orthopedic PEEK is one of the best replacement for metal while undergoing orthopaedic procedures, and particularly knee and hip arthroplasty. Dental PEEK, Cardiovascular peek, prosthetic peek, Hip-ball, Hip-stem, Bone screw all these peek require traceability.

Bone prostheses is the potential replacement of bones completely or partially. These bone prostheses are made up of substrates like non-reactive and non-corrosive metal, ceramic or highly cross-linked polymers. Whether they are metals like zircon or titanium, plastics or any polymer like polypropylene and acrylic they must follow all the medical compliance for traceability

Laser Marking Hygenic Peek

Marking on Fixation Peek

Marking on hipball implants

Medical related pages

JUJO Jelcon Inks

The ink dries at low temperature(80-90 degrees Centigrade). Ink film is flexible and tough to cope with moulding process. Heat resistance is excellent and the ink film is suitable to be used in insert moulding and in-mould processing. Moulding without binder is poss...

Read more

Hot Stamping Machine for Screen Printed Glass Objects

P50-MS-PR Screen Printed Glass Objects Machine with membrane or shaped silicon die. for hot stamping of glass objects previously screen-printed or varnished. Semiautomatic machine with mechanical rotary table. Printing using silicone membrane or silicone die. Opt...

Read more

Rucoinx pad printing inks

The pad printing method is used for decorating bodies that have no flat surfaces. Important fields of application include the decoration of toys and sales-promoting items as well as bottle caps, plastic bottles, decorative elements in the automotive and furniture industries ...

Read more

Screen Printing Inks

There are 4 types in printing; letterpress, lithography, intaglio and stencil. Stencil is used for screen printing just like mimeograph. Mesh(=screen) made of fabrics such as polyester is used for stencil. Screen is stretched and fixed to the frame. Resist is coated on the s...

Read more

Hot Stamping Machine for Pencils

MC-B1: Pencils Continuous kinematics machine for decoration of rigid cylindrical objects.. Automatic mechanical machine with continuous motion. Up to 5000 parts per hour. Printing using flat metallic dies. Optional second printing head and/or ...

Read more

Specialized Inks & Paints

Specialized ink for printing on untreated Polypropylene.High Gloss InkGives excellent surface smoothnessInk is highly viscous therefore gives high coverageEconomical in comparisonOur Inks are PVC freeIndustrial Applications:- SyringesBatteries- Automotive and InverterCa...

Read more

Hot Stamping Machine for Cylindrical Objects

CEREX-100-PR-M3: Cylindrical Objects. Automatic machine with mechanical vertical turret. Image foil application or full coloration. Up to 3000 parts per hour. Object cleaning before and after printing. CNC driven foil advance system with photo-eye cell. Loa...

Read more

Hot Stamping Machine for Counter Wheels

P50-CW: Counter Wheels Automatic CNC machine with bowl feeder. Up to 4000 parts per hour. Easy changeover with preset tooling. Object registration before printing. Hot stamping using steel die. ...

Read more