Mold designing

Injection Molding

Laser Marking/Pad printing/Spray coating

Assembly of Parts

Special thanks to our group capabilities to design & build automations, we can undertake complete automatic assembly lines. Pick & Place, Lubrication, Indexing, Pressing, Stamping, Drawing, Visual 2D & 3D, Inspection electrical testing can be integrated.

Spinks Softech is a well-known specialist of Molding, Coating, Pad Printing , laser Marking & Assembly of the automotive & electrical parts. All these technologies under one roof make it a winning combination for OEMs & gives us an edge over our industry colleagues.

We manage all forms of manufacturing, designing tooling, spray coating and surface treatments involved in the manufacture of Automotive, electrical and electronic components at its Plants in MANESAR, CHENNAI and PUNE which are the biggest hubs of automotive industry in India.

We are known for eye-catching spotless finishes on the components. We do pad printing, screen printing, foiling and laser marking decorations on thousands of other products which are found in our day to day modern lives.

AUTOMOTIVE APPLICATIONS

Parts & Specialization

Audio and Climate control are the central parts in success or failure of an automobile. A combined knowledge is needed to spray coat special high lighters, in chrome, Satin chrome, High gloss effects…

Our Specialization

Spinks which origins from special inks and coatings has vast experience in matching color and finish requirements meeting very strict automotive standards….

Colors and Inks

Our group company represents global brand like JUJO, Rucoink, DIEGEL for colors which are used all over the world in automotive business.….

Decoration of Logos

Making injection molded logos is entirely a special job. Although many companies are doing this….

Decoration of Gear Shifter Knobs auto gear Shifter panel

Requirements: Excellent printing sharpness followed by extremely hard top coating which can…

Decoration of Steering Wheel Parts

Making injection molded logos is entirely a special job. Although many companies are doing this….

Decoration of Speedometer Dials

MOLDED Speedometer dials decoration is a very specialized job. This is a new concept and only…

Decoration of Stereo Panel Parts

We are one shop solution providers comprising of special paints, inks and equipment…

Established in 2008, Spinks Softech is a premium single shop solution for Automotive Interiors and Exterior Parts. It has in-house capabilities of Mold Design, Mold Manufacturing, Injection Molding, Automatic Spray Painting, Pad Printing, Screen Printing, Laser Marking, and Child part Assembly. The company has 60+ injection molding machines varying from 40T-450T and 5 automatic spray-painting lines with 10K class dust level. Working with Spinks Softech is a seamless process with full customer satisfaction. We deliver high quality products on-time at the most reasonable price possible. Spinks Softech is a premium supplier to companies that want hassle free project completion on time, every time. With experience in the decoration industry for over 32+ years, Spinks Softech is known for being an industry leader for supplying the best automotive interiors. With our attention to detail, right from design to the final product, we are known for completing critical jobs for customers where manufacturing is difficult.

Headquartered in Manesar, with high quality established production facilities in Manesar, Chennai, and Pune. Spinks Softech supplies through a network of vendors to OEMs like Maruti Suzuki, Volkswagen, Hyundai, Kia, TATA, Mahindra & Mahindra, Toyota, Honda, etc. Some of our direct customers are Toyoda Gosei Minda, Spark Minda, Minda Rika, Kostal, Valeo, Marquardt, LS Automotive, Dayco, Nippon, Lumax Manoah, Harman International, Panasonic, Marquardt, Seoyon-Ewa, Magnetti Marelli, Phillips, Schneider Electric, etc. We comply with major automotive compliances like ISO 9001:2015, IATF 16949:2016, etc. Spinks Softech also has an SQ Mark from Hyundai and is categorized as a green category MACE supplier.

Spinks Softech is known for being an industry leader for supplying the best automotive interiors. With our attention to detail to the smallest things right from design to the final product, Spinks Softech is known for completing critical jobs for customers where manufacturing is difficult.

We are proud to say that we are the first company that has achieved the localization of car audio face plates.

We pioneered the backlit or back illumination day and night technology in India, which enables the driver to drive stress-free in the night without having to look at the cockpit while driving. We have, successfully served automobile companies and done it for many automotive OEM's for many years.

Sspecialized in high gloss piano black painting as well as chrome finish painting. It is a fully automatic spray painting and coating line from Europe with a 10,000 class clean room facility.

With all these facilities, precision and perfection, extremely tight tolerances and cost efficiency has become our strength. These attract our customers and give us a leading edge in technology. Our research team is continuously looking for new ways to cut costs, conserve resources and explore new eco- friendly possibilities of advancements and innovation in printing technologies. We definitely have a great future ahead. We sell complete solutions and do job works as well.

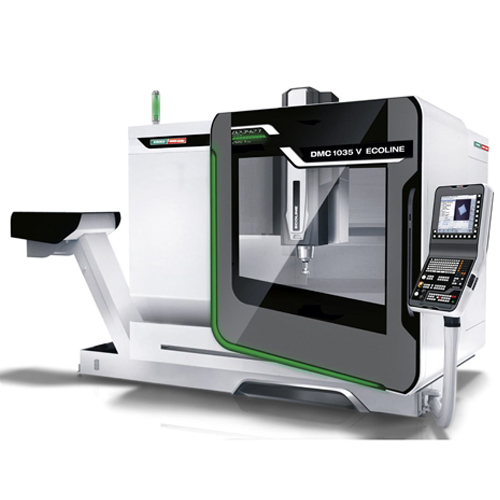

Mold Designing and manufacturing + Injection molding engine machines

Part Quality Inspections and ready to be spray coated

Spray Coating of molded parts

Laser marking for backlight, pad printing and finaly part assembly