Automotive OEM’s require highest quality standards for the automotive parts and components. Besides being and object of beauty with full functionality, the car interiors have to pass through rigorous tests to meet high industry standards of component decoration. These exceptional demands of automotive product decoration of the ever competitive automotive industry are met by various surface decoration techniques.

Spinks World qualifies all these expectations with ease, and has been in this sector for over 30 years, claiming to be one of the very few suppliers to major automaker OEMs for its cutting edge technologies in luxury spray coating, Pad printing of auto components, laser marking machines for traceability of auto parts, fully certified pad and screen printing inks, Heat transfers and foiling solutions.

You can trust Spinks as your partner for distinguished quality, reliability and services, from conception of a part development to the end product- all at one source. Check here for more details. Besides the services related to automotive part development that our subsidiary spinks softech undertakes, we deal in automotive surface decoration technologies that are a part of an automotive component journey. Spinks Softech also boasts of introducing the day and night backlit printing technology, which enables you to see the light through the part in the night.

What does Spinks World offer for printing and decoration solutions on Automotive Industry

Machines for printing and marking for the Automotive Industry

Spinks Softech, a unit of Spinks World, has pad printing machines, screen printing machines, laser machines (marking, cutting, engraving, texturing, deep engraving, 3D texturing) for the automotive industry. We are the manufacturer and distributor of these machines all over the world. These semi and fully automatic machines make the work fast and efficient, consume low ink, and less manpower with high production. Easy manufacturing, processing, and printing by these machines on automotive products/parts with a great finish and glossy touch stand us different in the automotive sector. In addition to this, Spinks World is coming with a spray coating machine in the coming months that will also become a big advantage for the automotive industry. Precision, durability, and flexibility while printing and marking on automotive gadgets/parts/items of any shape or size. Spinks World offers machines that range from stand-alone manual formulations to the automated machines.

EPIC Pad Printing Machine

Compact, simple, and environmental friendly high pressure pad printing machines

Printing inks solutions for Automotive Industry

The high standard printing demands of the automotive industry requires higher degree of diligence in selection of printing inks. Printing processes like Pad printing, Screen printing and Spray coating are used to print on automotive interiors which include Printing of logos, laserable parts, Combination switches, HVAC panels, Stereo faces, two-wheeler components, in mold decoration(IMD), Hazard Knobs, dash panels, formed metal, thermosets, climate control panels, push buttons, gear shifters, radiator caps, audio bezels, steering wheel controls only to name a few.

Whether for decoration or functional , for traceability identification or laser marking purposes, for Substrates such as PC/ABS/PMMA, PU, Coated plastics, Aluminum, Chrome plated plastics, Powder coated metals, Polypropylene PP, Nylon, PA 616,6, POM( Poly Oxy methylene) - for each of these fields suitable printing ink series that ideally meet the high quality requirements and safety regulations of the automotive industry. The major tests that an automotive component ink needs to pass are customer specific like TL 226/TL 221/ DBL 7384 or thermal requirements -40 to 180 C, Environment friendly, weather resistant to heat and cold, abrasion resistant, chemical resistant and an important detail to aesthetics and haptics. The major compliances that the printing inks must pass are ROHS, GADSL, REACH, Directive 2006/122/EC (PFOS), Directive 2005/84/EC (Phthalates), ASTM (D1475): Density of liquid coatings, inks and related products, ASTM (D2369): VOCs etc. Besides this, the inks in use must be bright, flexible, opaque, high adherence to the substrate and have high degree of chemical, extreme climate and physical resistance. Spinks offers a full range of pad and screen printing inks, UV, UV/LED, solvent based or conventional and hard coat inks for all the printing challenges for 2D/3D parts.

Pad and Screen printing inks

Automotive parts, automotive gadgets, automotive engines, automotive exterior and interior parts

Car interior, car exterior, car engines, push-button, steering wheel control, etc

Polypropylene (PP), Polyurethane (PUR),Poly-Vinyl-Chloride (PVC), ABS, etc

Screen printing ink

Automotive glass, Automotive bezel, Graphic display

1-2 component, Pad printing inks

silicone surfaces, automotive, automotive car seat cover, automotive foot mat, automotive silicone staring covering, gear shift silicone

High temperature curing screen printing inks, low temperature curing screen printing inks

Windshields, sunroofs, back lights, and side lights

Screen Printing Inks, Pad Printing Inks, and Spray Coating Inks

Dashboards, HVAC systems, Buttons, Speedometer, Panels, Infotainment systems, Steering controls, Knobs, ...

Consumables for Automotive Industry

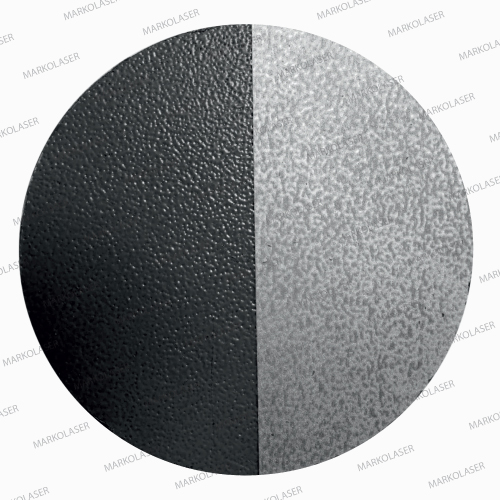

Silicone Pads

Special silicone pads are used in the pad printing to transfer the precise, sharp & high resolution image from the cliche to the surface to be printed. ...All silicone pads are readily available on demand as they are 'Made in India' with International standards.

Cliché plates

Cliché Plate material, depth, size, toughness, lapping & etching and grounding are some key factors that make it perfectly suitable for pad printing ...based on the application for excellent printing results.

Automotive Product decoration

We are the manufacturer and designer of Automotive interior With extensive experience and know-how of more than 25 years as Automotive decoration specialist, we are the who introduced backlit technology in automobiles in India and boast of a list of satisfied automobile companies. With the use of best German pad printing technology from inks from Rucoinx Germany and finest lasers from Markolasers, we have achieved perfection in decoration of automotive components, electrical and electronic parts to name a few.

High performance and premium quality Automotive compliant UV Screen printing inks, pad printing RUCOINX inks are designed specifically for automotive interiors that includes dash panel, formed metal and thermoset applications.

Audio assembly

- Injection molding - spray coating - chrome plating (outsourced) - heat stacking

- Injection molding - spray coatingchrome plating (outsourced) - light guide assembly - heat stacking

- Injection molding - spray coatingchrome plating(outsourced)-assembly

- Injection molding - light guide and felt assembly

Audio Screen

Acrylic sheet molding, 5-layer screen printing

Hazard button

Drive mode selector

Auto hold button

Fog lamp

Bike holder casing

USB, Aux casing holder

Injection molding - Spray coating - laser marking

Injection molding - Spray coating - Pad printing

Automotive Product Decorations

Spinks group represents global ink brands like RUCOINX, Merlia etc. These are high quality, special inks used for decorating, screen printing, pad printing, luxury spray coating automobile parts.

These light, weather and temperature resistant inks are used in automotive sector for Spray coating, pad printing, screen printing, product decoration and day-night

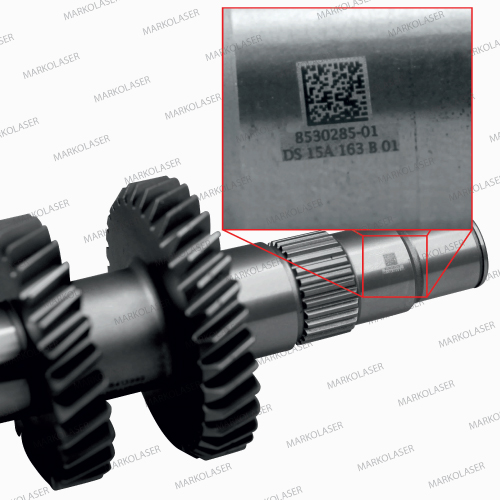

Laser DPM on Automotive Parts like Gears, bearing, engine parts, crank shaft,

PCB, Tyres for Traceability, Laser Marking Machine and Automations

We follow all DPM & Label Code Quality Standards

ISO/IEC

TR 29158

ISO/IEC

TR 24720

ISO/IEC

TR 16022

ISO/IEC

TR 15415

DOD

UID

SAE

AS 9132

FDA

GSI

FDA

CFR21

With over 30 years of experience and dedicated team of engineers, we have set unprecedented records in providing customized automation solutions to numerous market leaders. These automation solutions include making fully automated assembly lines, providing printing and laser automation solutions etc.

We manufacture industrial pad printing and laser machines for automotive sector.

Laser Marking of Data Matrix Codes on Automotive Gears for Traceability

This is an outstanding example of a complete "Traceability Solution". This semi-automatic machine laser marks and verifies the marked data matrix code on all gear transmission assembly parts. Additionally, it is equipped with an integrated traceability system.... Read More

Multiple colour shade printing on Alloy wheels & caps

What does Spinks World offer for printing and decoration solutions on Automotive Industry

Machines for printing and marking for the Automotive Industry

Spinks Softech, a unit of Spinks World, has pad printing machines, screen printing machines, laser machines (marking, cutting, engraving, texturing, deep engraving, 3D texturing) for the automotive industry. We are the manufacturer and distributor of these machines all over the world. These semi and fully automatic machines make the work fast and efficient, consume low ink, and less manpower with high production. Easy manufacturing, processing, and printing by these machines on automotive products/parts with a great finish and glossy touch stand us different in the automotive sector. In addition to this, Spinks World is coming with a spray coating machine in the coming months that will also become a big advantage for the automotive industry. Precision, durability, and flexibility while printing and marking on automotive gadgets/parts/items of any shape or size. Spinks World offers machines that range from stand-alone manual formulations to the automated machines.

Printing inks solutions for Automotive Industry

The high standard printing demands of the automotive industry requires higher degree of diligence in selection of printing inks. Printing processes like Pad printing, Screen printing and Spray coating are used to print on automotive interiors which include Printing of logos, laserable parts, Combination switches, HVAC panels, Stereo faces, two-wheeler components, in mold decoration(IMD), Hazard Knobs, dash panels, formed metal, thermosets, climate control panels, push buttons, gear shifters, radiator caps, audio bezels, steering wheel controls only to name a few.

Whether for decoration or functional , for traceability identification or laser marking purposes, for Substrates such as PC/ABS/PMMA, PU, Coated plastics, Aluminum, Chrome plated plastics, Powder coated metals, Polypropylene PP, Nylon, PA 616,6, POM( Poly Oxy methylene) - for each of these fields suitable printing ink series that ideally meet the high quality requirements and safety regulations of the automotive industry. The major tests that an automotive component ink needs to pass are customer specific like TL 226/TL 221/ DBL 7384 or thermal requirements -40 to 180 C, Environment friendly, weather resistant to heat and cold, abrasion resistant, chemical resistant and an important detail to aesthetics and haptics. The major compliances that the printing inks must pass are ROHS, GADSL, REACH, Directive 2006/122/EC (PFOS), Directive 2005/84/EC (Phthalates), ASTM (D1475): Density of liquid coatings, inks and related products, ASTM (D2369): VOCs etc. Besides this, the inks in use must be bright, flexible, opaque, high adherence to the substrate and have high degree of chemical, extreme climate and physical resistance. Spinks offers a full range of pad and screen printing inks, UV, UV/LED, solvent based or conventional and hard coat inks for all the printing challenges for 2D/3D parts.

Pad and Screen printing inks

Automotive parts, automotive gadgets, automotive engines, automotive exterior and interior parts

Car interior, car exterior, car engines, push-button, steering wheel control, etc

Polypropylene (PP), Polyurethane (PUR),Poly-Vinyl-Chloride (PVC), ABS, etc

Screen printing ink

Automotive glass, Automotive bezel, Graphic display

1-2 component, Pad printing inks

silicone surfaces, automotive, automotive car seat cover, automotive foot mat, automotive silicone staring covering, gear shift silicone...

High temperature curing screen printing inks, low temperature curing screen printing inks

Windshields, sunroofs, back lights, and side lights

Consumables for Automotive Industry

Silicone Pads

Special silicone pads are used in the pad printing to transfer the precise, sharp & high resolution image from the cliche to the surface to be printed. ...All silicone pads are readily available on demand as they are 'Made in India' with International standards.

Cliché plates

Cliché Plate material, depth, size, toughness, lapping & etching and grounding are some key factors that make it perfectly suitable for pad printing ...based on the application for excellent printing results.

Automotive related pages

Hot Stamping Machine SF350 and SF600

SF350 & SF600 Automatic stepper feeder. 4000 to 6000 parts per hour. Programmable PLC for main parameters adjustments. Easy connection with CER range of machines. Optional mechanical pick & place with orientation. ...

Read more

Hot Stamping Machine for Cosmetic Products

QUADRAX: All shaped cosmetic products and more.. Automatic 3 or 4 CNC axis printing machine.Shape object is scanned by laser beam.Various printing processes: flat silicone die, silicone roller for image foil application or coloration, screen-printing.Excellent and...

Read more

Markolaser Express Series

Markolaser: Fiber Laser Marker ” 10W / 20W-DE / 20W-DE / 30W-DE / 70W-DETop of the line - mean and tough industrial lasers for small to heavy parts. Finest quality components procured from around Europe are integrated by our experts to perform even the most difficult tasks...

Read more

Soft Plastic Tubes Stamping Machine

TUB - 60 & TUB - 250 : Soft plastic tubes Servo-controlled machine dedicated to hot stamp soft tubes Longitudinal and transversal registration carried out by a CCD camera. Inclined ramp feeding. Printing head equipped with two servo motors to correct the p...

Read more

Hot Stamping Machine for Screen Printed Glass Objects

P50-MS-PR Screen Printed Glass Objects Machine with membrane or shaped silicon die. for hot stamping of glass objects previously screen-printed or varnished. Semiautomatic machine with mechanical rotary table. Printing using silicone membrane or silicone die. Opt...

Read more

Greeny MARKOLASER for Glass

Greeny MARKOLASER for Glass, Crystals & NylonOur green laser is a diode pumped, Q-switched, solid state laser. We use the finest micro resonator with electro-optic modulation technology which is perhaps one of its kind. Our laser diodes are of best quality . These pumpin...

Read more

JUJO Jelcon Inks

The ink dries at low temperature(80-90 degrees Centigrade). Ink film is flexible and tough to cope with moulding process. Heat resistance is excellent and the ink film is suitable to be used in insert moulding and in-mould processing. Moulding without binder is poss...

Read more

Hot Stamping Machine for Plastic Containers and Automotive Parts

H100 & H1500: Plastic containers (crates, pallets, waste bins.) and Automotive Parts (front grid, tail light, engine cover.) Semiautomatic direct acting hydraulic machine: up to 15 tons pressure. Motorized table for height adjustment. Adjustable guides ...

Read more

.png)