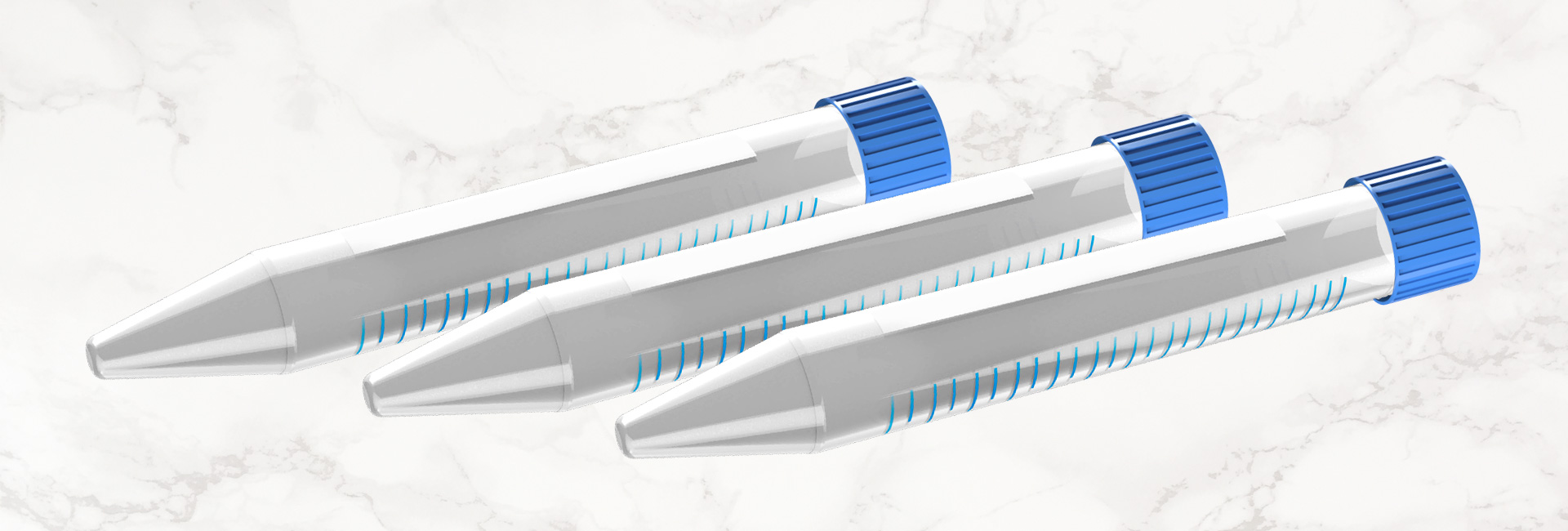

Printing solutions for polypropylene centrifuge medical tubes

About Centrifuge Tube:

A centrifuge tube is a high quality, precision-made, ultra-clear, USP class VI medical grade polypropylene, polystyrene, polycarbonate, or polyethene plastic tube of high strength complying with US FDA 21 CFR, used in medical labs for volumetric analysis of immiscible samples in serology. These tubes are very precisely graduated for maximum accuracy for the estimation of samples. Made from high-quality FDA approved virgin plastic.

|  |

The Certified Microcentrifuge Tubes are manufactured from FDA approved resins and are certified to be RNA, DNA and Pyrogen free.

The printing for calibration / marking on centrifuge tubes is generally done in two colors. The graduation or calibration is mostly done in blue or black colors and special writable, scratch-free, white frosted matt ink is used to print a white patch on the centrifuge tube to write with a marker on it for traceability and identification. The inks need to withstand sterilization like UV irradiation, ethylene oxide, formalin, ethanol, benzalkonium, chloride, hydrogen peroxide, sodium hypochlorite, glutaraldehyde, phenolic derivatives, etc., can be autoclaved, resistant to high salt conditions, freezable and must be made of clear plastic to see through the graduation/ marking/ calibration clearly. Gamma irradiated sterile. The printed graduations need to be extremely clear, bold & easy to read.

The centrifuge tube calibration is usually done with white and blue colors. At times black inks are also used for graduation to allow easy viewing of measurements in the tube.

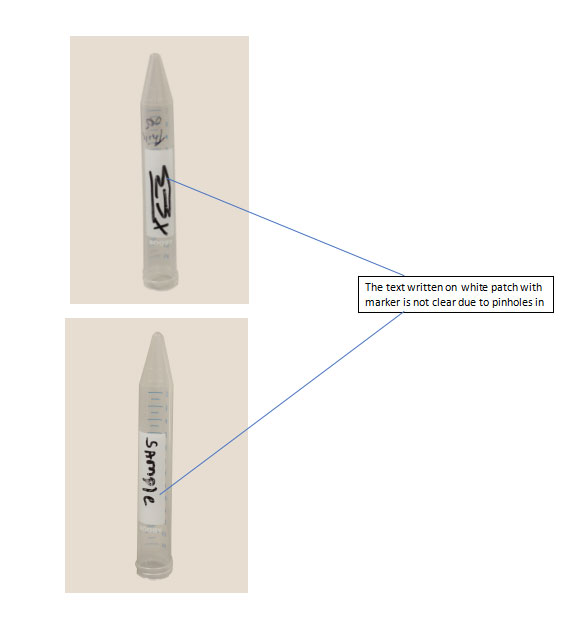

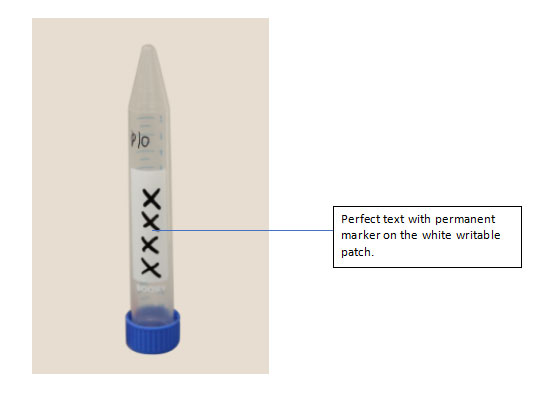

The sides of the tubes often have a clear white patch for labelling. This is known as a writable patch. The patch can be printed or handwritten with a marker pen to increase sample traceability. The marker should be able to write clearly on the white ink patch.

| The white writable patch must be -

|

Spinks World has special inks from

The special offering is 085UV series dry offset ink for printing on preformed 3D plastic tubes dealing with all issues of -

- Adhesion

- High migration

- Press speeds

- BPA free

- Conformance to medical standards

- Low odor according to DIN 1230 (Robinson test)

Laboratory consumable manufacturers, researchers and bioprocessing communities are busy these days manufacturing Centrifuge tubes and other testing consumables for blood and urine testing in wake of COVID-19.

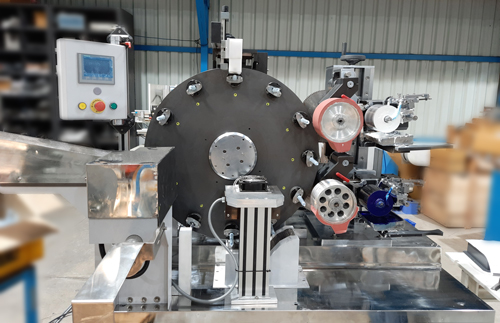

At Spinks World, we have sufficient inquiries from the diagnostic equipment manufacturers looking for fully automated pad printing machines and relevant medical grade inks for the graduation, calibration and markings on the ultra-clear polypropylene, premium-grade polystyrene or polyethylene tubes in all sizes and variations.

Centrifuge tubes, injectors and other round medical container pad printing high-speed automation for scale, legend and white spot printing.

Clear accurate black or blue color printed graduations, calibrations or scales on the centrifuge tubes.

White label, square white patch or a marking spot printing on the centrifuge tubes for easy writing on the tube for identification and traceability purposes.

Spinks Impex makes a variety of machines for printing onto all types of medical tubes, offering a range of speed, colour, adhesion and handling capabilities to suit almost every requirement. This automation is capable of automatic feeding, pre-treatment, printing, curing, automatic unloading, inspection and other processes for ultimate user -friendliness and extreme versatility.

The featured centrifuge tube printing automation is

- Fully Automatic – giving a speed up to 2000 parts per hour.

- Has Corona pretreatment feature to improve adhesion of inks.

- Two colour high registration printing ( white color to print a writable patch and blue color for graduation printing on plastic/glass centrifuge tubes)

- Infrared post pad printing curing accessory to accelerate drying of ink.

- Auto unloading

- Flexible interchangeable mandrels for different variants

- Easy & fast changeover from one variant to another.

Check out the centrifuge printing automation on our YouTube link.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations.

Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

Write to us at info@spinksworld.com to know the special UV dry offset inks needed for calibration and the special writable white inks for printing patches onto these medical PP tubes.

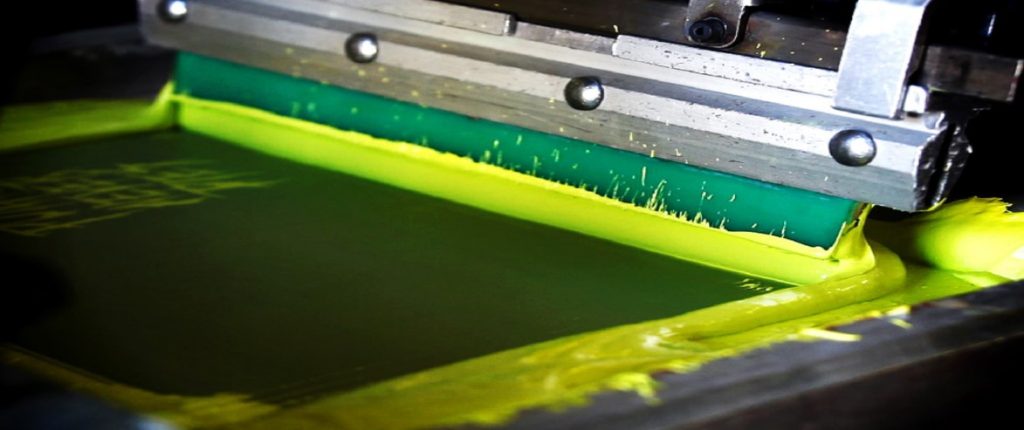

Screen printing ink

Pad Printing Solutions in Chennai

Pad Printing Solutions in Bangalore/Bengaluru