Non-toxic Printing Inks and Pad Printing machine for Printing on Disposable Syringe

Disposable syringes are one-time usable medical consumable. Hypodermic syringes have a hollow needle attached to a syringe which helps pierce the skin and inject medicines into the bloodstream. However, they can also be used to extract blood and other fluids from the body. Legislation Title 21, of the Code of Federal Regulations (CFR), governing the labelling and coding of syringes is an essential safeguard that protects the health of patients. Syringes are made up of clear PP (Polypropylene) (clarified medical grade).

Scale and logos are printed on them for calibration. PP is a plastic from the family of polyolefins with a surface tension of 30.9 mN/m. And, clarified PP is the specialized Polypropylene which has glass like clarity, excellent moisture barriers properties, hot filling capacity and low cost, making it the ideal packaging material for food, beverages, optical media, house wares and medical products. To a great degree, ink adhesion depends on the surface energy of the substrate, which must be greater than the surface tension of the ink. Polyolefins, such as polypropylene and polyethylene, have a low surface energy and need to be pre-treated to raise the surface energy. Generally three methods can be used: Flame, Corona or Plasma treatment to improve ink adhesion.

Colours used in syringe printing are generally Black/Blue/Red.

Pad printing makes markings, scales, and decorations possible where other processes reach their limits

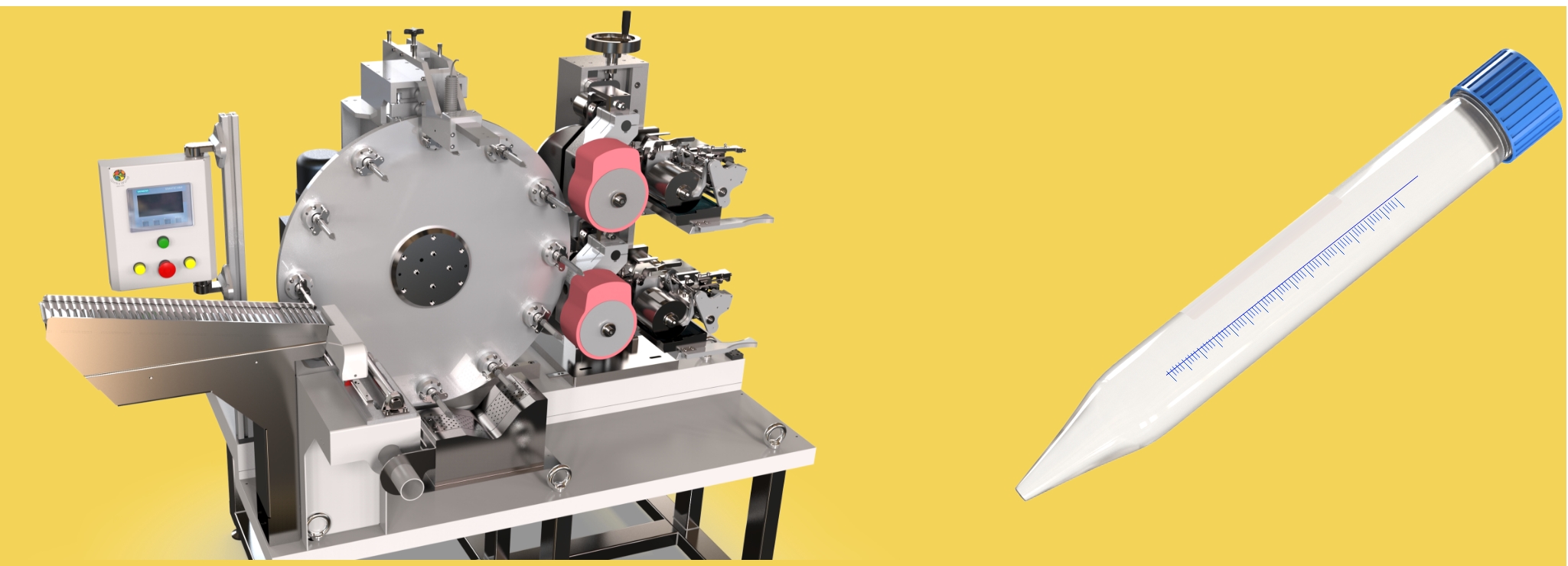

Rotary Pad Printing:

Ink is applied on an engraved roller which is cleaned by a blade to trap the ink inside which is subsequently picked up by a rubber roller. This rubber roller comes in contact with the syringe barrel to deliver the print. The printing line has been designed for printing on disposable syringes with different diameters. The output is 16.000 - 20.000 parts / hour, depending on the size of the syringes. Pad printing makes markings, scales and decorations possible where other processes reach their limits

Rotary Pad Printing: Syringe printing Ink must have the following properties to deem fit for printing application on syringes:

- Compliance with non-toxic norms like EuPIA Exclusion Policy,

- REACH regulation (SVHC) , Swiss Ordinance (SR 817.023.21), Canadian Hazardous Products Act (R.S., c.H-3, s.1.), USP Medical Class VI (exclusively for black T-200), Compliant with the current European standard EN 71-3 , Compliant with the current European standard EN 71-9 (exclusively for basic color shades T-200, white and black), RoHS compliant (2015/863/EU) // (2011/65/EU).

- Free from heavy metals, formulated free from BPA, phthalate-free, fluorine-free, bromine-free.

- Must be opaque.

- Must adhere to P.P. with or without pretreatment.

- Must be able to dry fast enough just to transfer on the syringe. If slow then it will get smudged and if too fast, then it will dry on the steel roller or the rubber roller.

- Must be able to sustain EOG or ethylene oxide gas sterilization

Medical grade inks (RUCOINX)

Safety must be considered before labeling the medical medicinal devices and Syringes. Printing inks must also be non-sterilizing and must comply with unique sensitive Medical product compliance and FDA(Grade) guidelines. In addition, it essential that the inks or chemicals used in printing the character and measurement of the syringes must not get into the human body. In addition to the sterile syringes, braces, and hearing aids, medical items may be labeled and decorated with pad printing.

- RUCOINX T25 PP Ink (untreated polypropylene)

- RUCOINX T 200 (pretreatment needed)

- RUCOINx T 400 PP (untreated polypropylene)

Additional additives to improve adhesion to PP available

*Pl. Test before using & use as per TDS.

For more information email: info@spinksworld.com

Training and Consultancy

Spinks Believes in total customer satisfaction right from the day a prospect walks in with a printing/ laser marking problem, to deliveries of machines, inks or consumables till the customer is ready to begin printing operations independently. We offer full-fledged training and consultancy when you buy the first system/ machine, inks or consumables from us. We provide training at our facility or at your place, completely at your discretion.

Pad printing machine training

Spinks World not only educates its consumers on how to use or manage a pad printing system but also ensure that consumers are interested and appreciate the whole printing process. The involvement of the operator is a must to learn the complete process. We walk them through the entire process, beginning with artwork preparation, plate design, plate selection, pad picking, ink mixing, and ending with equipment and fixture fabrication. We agree that our coaching and training give customers trust in the whole process and allows them to get the most out of our knowledge.

The expert trainer keeps a special attention on:

How to set up a pad printing system, execute processes, make changes, and troubleshoot glitches. Proper ink transfer and its association with plate etching depth, ink/solvent blend, and pad quality necessitate special consideration. The trainer meticulously focuses on selecting the correct pad based on the system, component, and artwork to be pad printed and setting the suitable parameter to etch the plate well.

Training at Spinks World facility

We firmly advise you to come to our facility for full-fledged free training after purchasing the pad printing machine from us. We would make you practice in the most efficient manner possible because we have all of the required facilities for training. Second, we have a team of professionals with extensive expertise. They have a better opportunity to answer your questions and direct you.

At Spinks world, we not only teach customers how to operate a particular machine – we make sure the customer understands the entire printing process, both fundamentals and fine details. We will walk you through everything from artwork preparation and plate making (if needed) to pad selection, ink mixing, using equipment and fixtures – so you feel confident and can get the best from our products.

On-site audit of printing processes

Many of our clients, ranging in scale from small to big, require our audit services. In this service, we send our specialist technicians to recheck and inspect the instruments and processes used in manufacturing and find areas for improvement. Spinks World encourages customization and high production while reducing costs by staying on the cutting edge of technical advances and having years of expertise in the printing inks for the medical industry.

Training at customer’s factory

Spinks World arranges training sessions and coaching to be held at your factory. Our consultants will come to your place and educate your employees on how to successfully demonstrate the machine's operation. We conduct training sessions together in the case of a big purchase (a large number of machines) or a large number of people who need to be qualified.

Training courses are scheduled based on availability. Training can last a single day or several days and can be broken down into several parts, delivered to various shifts and management (training management is also a positive thing because it allows managers a greater view of the production challenges), and so on.

We provide Pad Printing Machine in Faridabad, Lucknow, Indore, Nagpur, Patna, Meerut, Ludhiana, Amritsar, Chandigarh, Gwalior, Mysore, Ranchi, Bhopal, etc.

Mail us at info@spinksworld.com to contact us in this regard.

Disclaimer:

This disclaimer informs readers that the views, information, and opinions expressed in the text belong solely to the experts or professionals working in the same field of study. However, the customers are required to test for themselves before going into productions. All the presented information stems from the rich and varied 30+ years' experience of organization in the printing business.

Pad Printing Machine in Faridabad

Pad Printing Machine in Lucknow

Pad Printing Machine in Indore

Pad Printing Machine in Meerut

Pad Printing Machine in Ludhiana

Pad Printing Machine in Amritsar

Pad Printing Machine in Chandigarh

Pad Printing Machine in Gwalior

Pad Printing Machine in Mysore

Pad Printing Machine in Ranchi

Pad Printing Machine in Bhopal

Printing Solutions for Feeding Bottles

Printing of Medical Ampoule Strips: Machines & Inks

Printing inks ( Solvent Based ) for Glass

Face Mask Tagless Printing Solutions