Printing inks for Glass

UV Glass Inks: -

A brief description 935UV

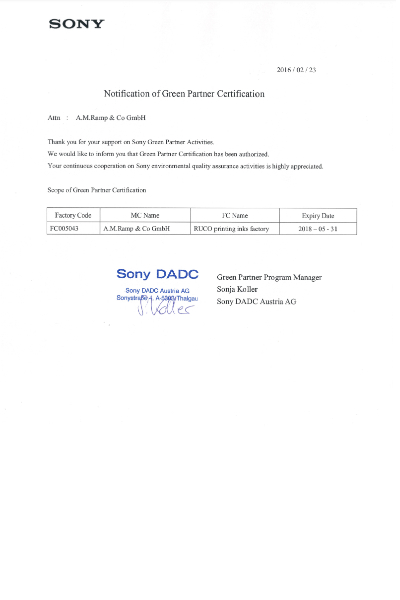

RUCOINX, Germany has recently launched very special ink series in India for Glass applications- UV Glass inks.

These inks are special due to the following reasons:-

1. Glass industry across the globe is forced to use inks containing heavy metals.

2. These heavy metal inks require high temperature, making energy consumption higher

Advantages of RUCOINX UV Glass Series:-

No post baking at high temperatures required.

Low energy required because no LEHR required.

Free from Heavy metals which form the basis of all inorganic inks used for conventional glass industry.

High speed curing. Some machines work even at the speed of +3500 bottles per hours in 4-6 colour.

Since few colours can produce many colours, unlike ceramic colours, we have higher success in multicolor reproduction.

For more information Scroll downFor detail please visit RUCOINX WEBSITE : www.rucoinks.com

RUCOINX T-01 Screen/Pad printing

Opaque colors: White, Black, brilliant and vibrant colors are available as standard T-01 series.

However for the 3C industry which demands HF inks, RUCO-T01 HF and T-00 HF complete the entire range of products. RUCOINX HF inks are compliant with latest norms of European Union like REACH, ROHS, HF etc.

Printing on glass requires very high optical density. Optical density of log 2 is achieved with opaque black T0I HF and above optical density of log 4 with T01 HF and grey ink overprinted.

With RUCOINX thermal hardener even with 2-5% addition can give very good bonding on glass with a surface energy going upto 50Nm/m.

1. Cosmetic containers like bottles of perfume and oil. (T-20, T-01, T-28, 110KK, 110GE)

2. Touch Panels, Capacitative Touch Panels of electronic devices. (T-01 HF)

3. Acid wash effect ink and coating RUCOINX have an interesting solution to replace the toxic and dangerous acid etch by Hydrogen Fluoride Acid (HF acid). Applications are done by spray coating or screen printing.

4. Over foiling or Inline foiling A special inline screen printing ink is screen printed followed by foiling only on the screen printed surface.

Printing on Glass by UV+LED Screen printing inks

RUCOINX, Germany started conventional UV screen printing inks for glass, hollowware, drinkware and cosmetic packaging in 2012. RUCOINX UV Ink 935 UV is a market leader in this category. At the same time, the research team at RUCOINX also developed an ink suitable for both UV and LED. Now we are introducing the 937 UV+LED inks. With the introduction of new series in 2018, the glass printing business has taken a dynamic turn. Customers using very high speed machines of Kammann, Omso or Fermac can use the same ink for curing by conventional UV or LED lamps. Speed of over 120 glass parts per screen per minute is easily achieved. view more The major advantages of this ink over conventional inks are :

.avif?ruco_certificate/HACCP-concept,-BRCIoP-standard,-IFS-6-(International-Food-Standard).jpg)